Why Job Shop Growth Stalls

I recently had one of our customers ask me an important question about job shop growth as he prepares to take over his family’s job shop:

“What keeps shops from growing past a certain point and what/where is that point?”

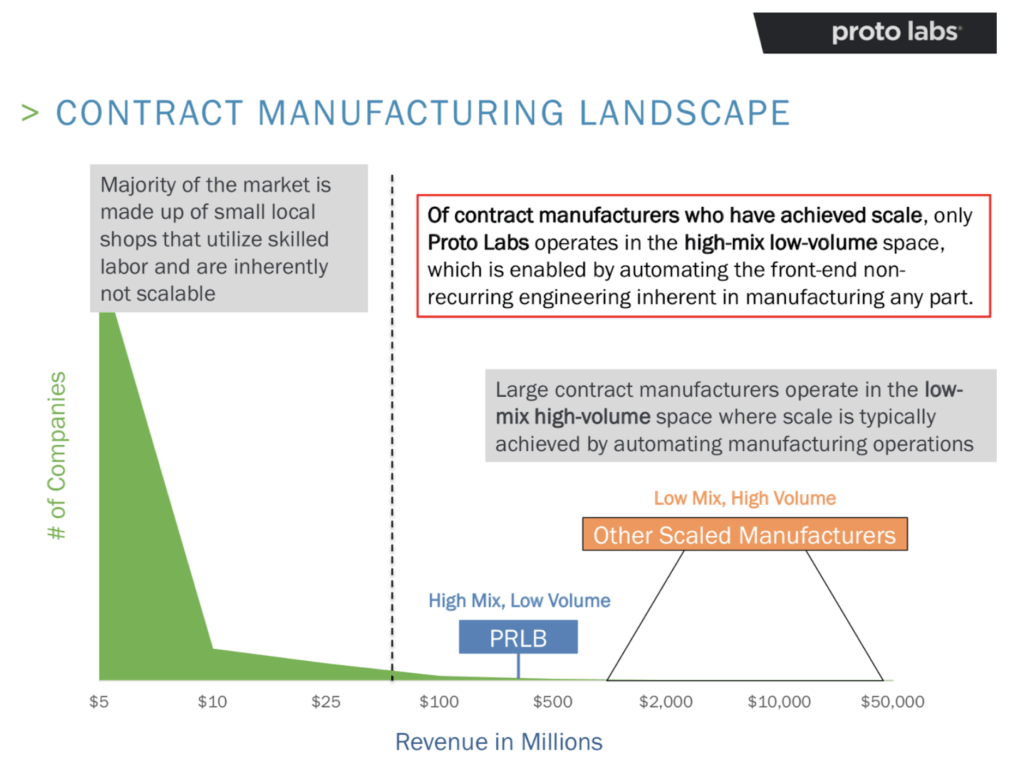

The first part of the question is addressed by common roadblocks outlined below. Regarding the point where most shops stall, there are over 30,000 US job shops and contract manufacturers with the vast majority of them falling under $10M in revenue. I usually see job shops stall somewhere less than $5M in revenue (which is also shown in the image below provided by ProtoLabs).

Exploring why shops stall, here are some common roadblocks:

Owner Mindset

In the job shops Jay Jacobs and I have seen and visited, the owner becomes the bottleneck. Typically not trained in business, these highly skilled owners try to do too much themselves. They have not learned how to move from a “Rugged Individualist” to the “Team Head Coach” and empower their team. Delegation is a learned ability and it takes a conscious effort to develop the trust required to delegate (Paperless Parts is developing a program to help job shop owners learn how to become a Team Head Coach – contact us for more information).

Shop Footprint and Shifts

Sooner or later the shop simply runs out of room to add equipment. A shop may have the option to rearrange equipment but this expense may be viewed as too costly (note: many banks will lend for this type of expansion, particularly if new machinery is purchased at the same time). If more space in the current shop is not available, a shop can move to a larger space. However if a shop owner also owns the building, it is often difficult mentally to make a move to a new building. Another option, which requires developing the team first, is to add shifts and or run lights out. This is the potential difference between a $3M and a $9M operation in the same footprint.

Customer Concentration

Most shops typically have three to five customers accounting for 80+% of their sales. This is known as “High Customer Concentration”. Losing any of them will cause big problems and as a result the shop becomes captive to them. These customers are in a position to dictate unreasonable terms such as free expedites or annual price decreases. Shops also keep capacity open for these large customers rather than filling it with orders from new customers because they are afraid of losing the current customer if they can’t fill last minute critical orders. Critically, quotes for new customers who may free them from the customer concentration issue go to the end of the queue when existing customer requests appear.

Lack of Investment

Understandably, owners like to enjoy the fruit of their effort and take cash earned in the good years to use outside the company. But cash is required to grow. An owner committed to growth will put money back into the business. They invest in new equipment, people, space and–increasingly today–software like the Paperless Parts Platform. Lack of cash keeps shops from expanding to multiple shifts. Extra shifts leverage the investment already made in space and equipment with machines running 120 hours a week rather than 50. Third shift may require a high hourly rate but a few really skilled 3rd shift workers making an extra $5 per hour, dramatically increases revenue. At RAPID, the investment in 2nd and 3rd shift team members saw dramatic revenue gains (see this article by Jay Jacobs on the topic of multiple shifts), more than covering the extra hourly pay.

Results

Pushing a job shop to continually grow is hard work. In the end, many owners decide growth is uncomfortable and that a “lifestyle” business capping out around $3.5M in sales is less risky. Unfortunately, this leaves the owner with a shop that is very challenging to sell or transition to new ownership when it comes time for retirement.

I will talk about this more on a future a post on job shop valuations. In the meantime, contact us to understand how Paperless is supporting job shop owners to push past the stall point without working harder or adding risk.

Jason Ray is the Co-Founder & Chief Executive Officer at Paperless Parts. Jason drives the company’s product vision, while building relationships with manufactures and partners. Before Paperless, he served as an officer in the US Navy and led the implementation of additive manufacturing technology. Jason holds a BA (Trinity) and MBA (Babson).