What’s New in Paperless Parts – March 20, 2019

We have some big updates this week on Paperless Parts including the new Operations interface, new manufacturing processes, better tracking of quote views, and improvements to Online Metals pricing recommendations!

Quote with the New Operations Interface

We received a lot of feedback on the old quoting interface. Customers often asked us where the pricing came from for the parts they were quoting. Additionally, they wanted to capture more details about what goes into pricing the part. We took the feedback and finally, here is the result: Operations.

Full Transparency in the Quoting Process

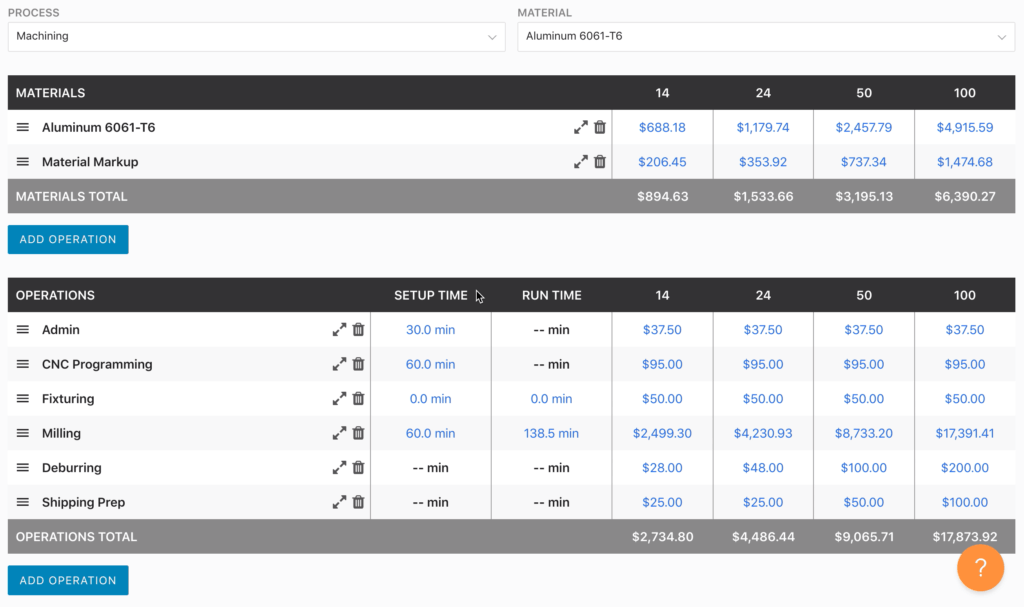

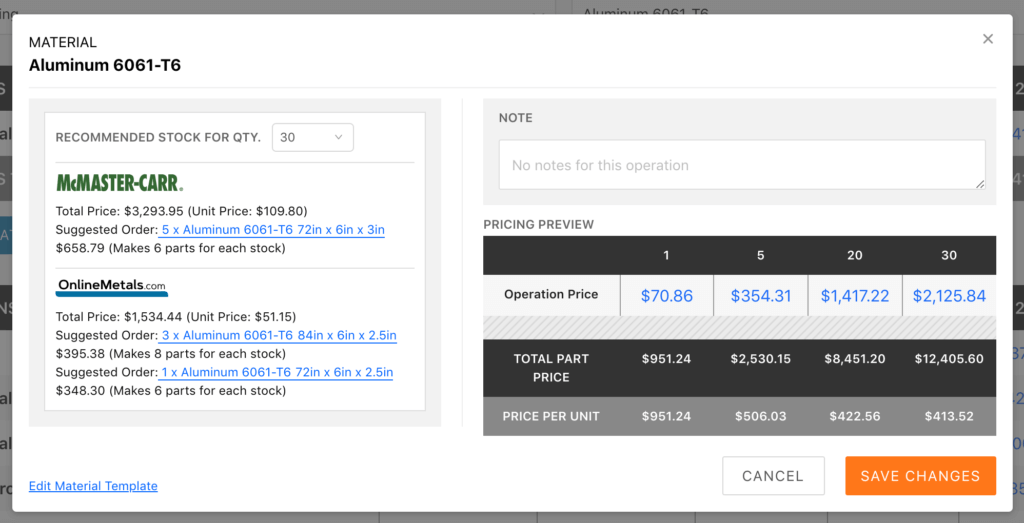

With the new Operations interface, you can now see exactly how the price is generated for your parts. The Build Quote page now presents the Operations interface to provide full transparency of what drives pricing:

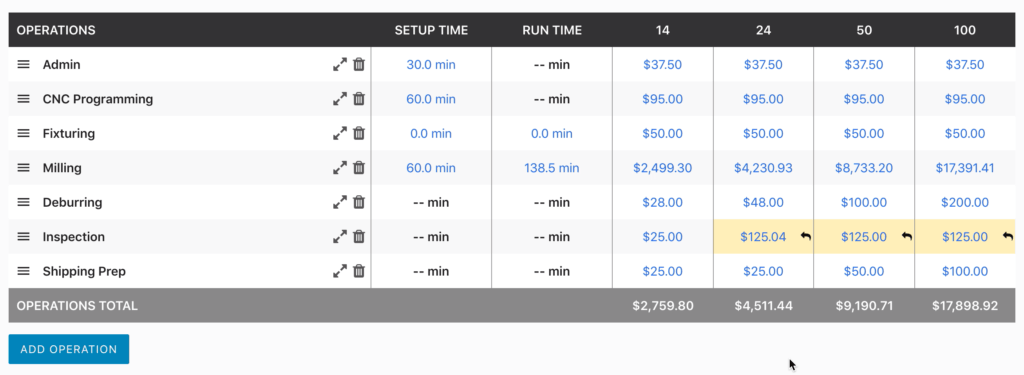

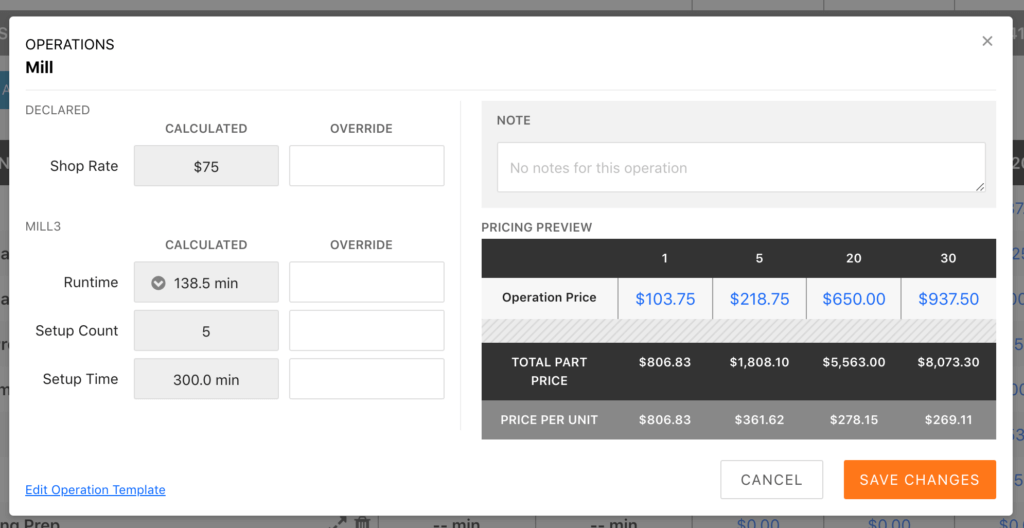

With more granular control, the Operations interface lets you set and override setup time, run time, and other variables you use for pricing. As you and your team manually override values, these inputs are highlighted in yellow to better track these changes.

This transparency Operations provides is especially helpful in the following ways:

- When you refer to a historical part based on geometric matching of similar parts, you can see exactly how that part was quoted including all the overrides applied. This saves you time in the quoting process so you do not have to start from scratch.

- The Paperless Parts Platform uses the manual overrides to improve the algorithms on the platform.

- The operation format mirrors how ERP systems work, making the integration between Paperless Parts and your ERP system much more seamless.

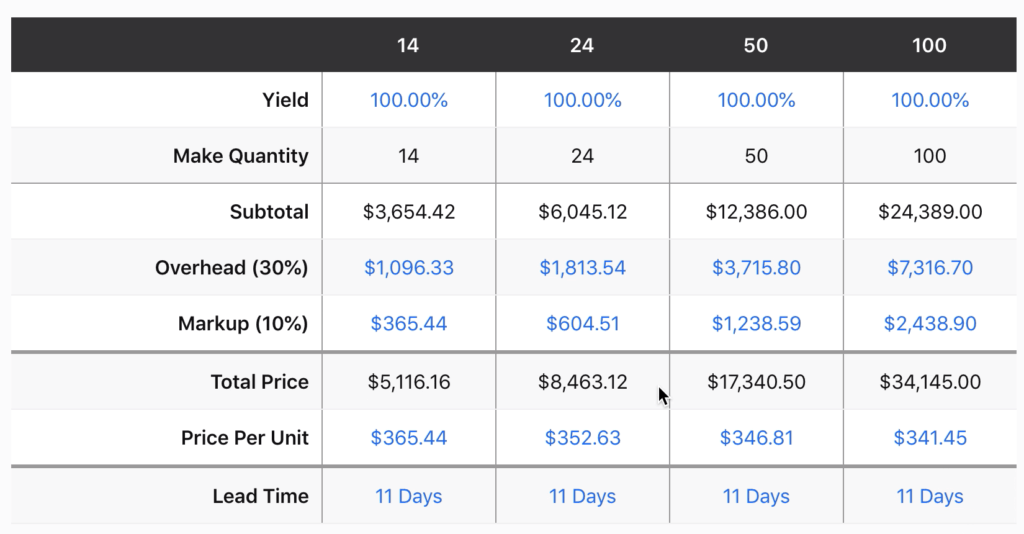

Operations also come with improvements in the pricing summary for each quote item. You can now see additional information that goes into your pricing including the Yield %, Make Quantity, Overhead, and Markup. These variables can be configured to however your shop wants to use them.

Configurability to Match How You Want to Quote

With Operations, the configurability of the platform has increased significantly. Each Operation can be configured to use your own variables and formulas, as well as the geometric interrogation performed by the platform. This means that the system has the full flexibility to capture however you want to price parts.

Note: We are rolling out operations to our current customers as we update your existing processes to use operations.

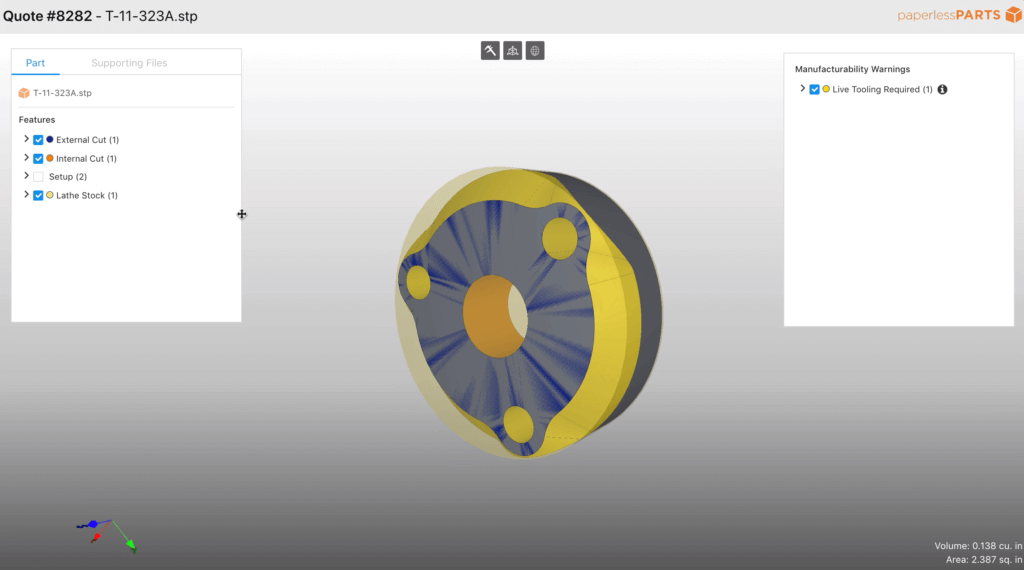

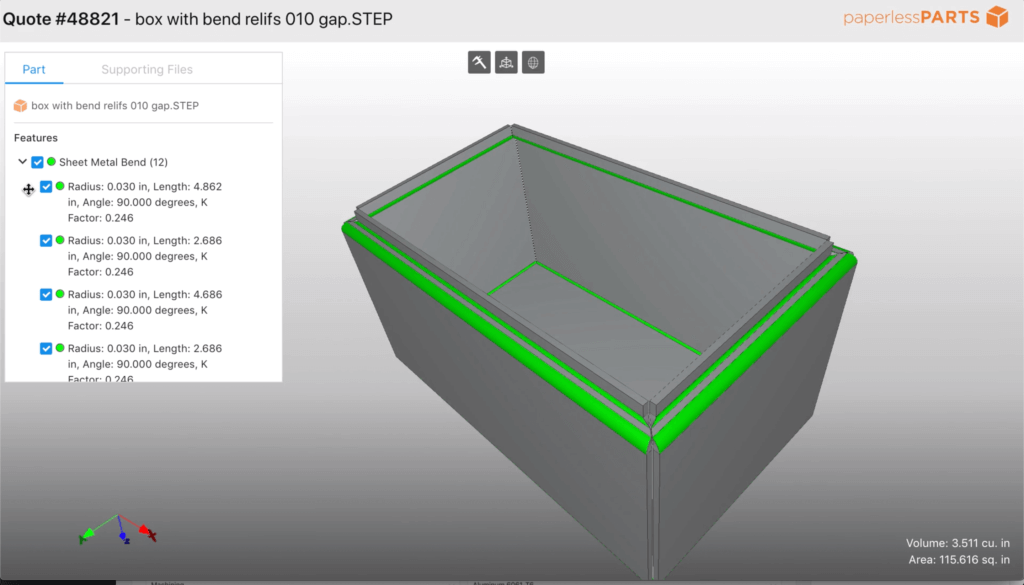

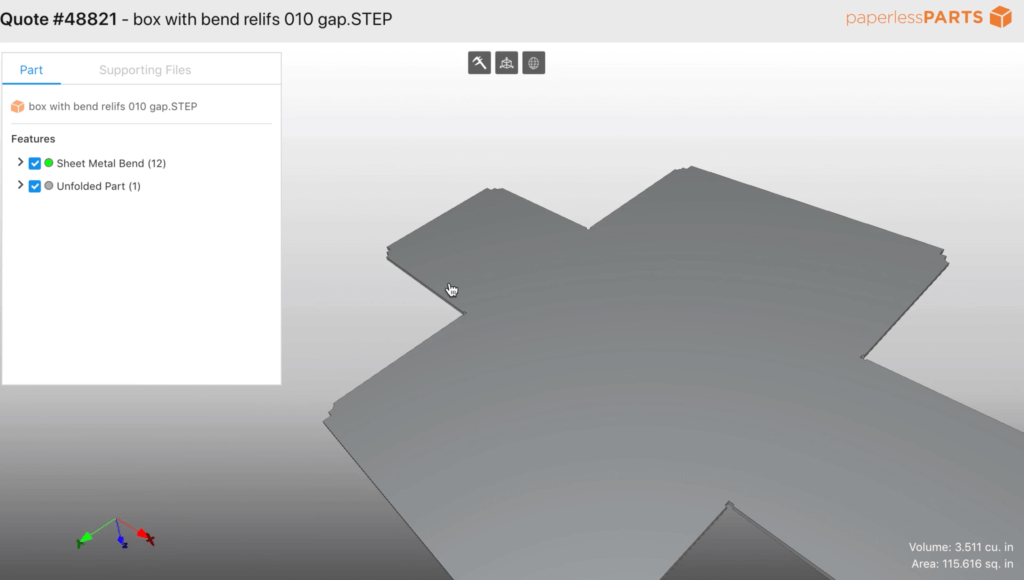

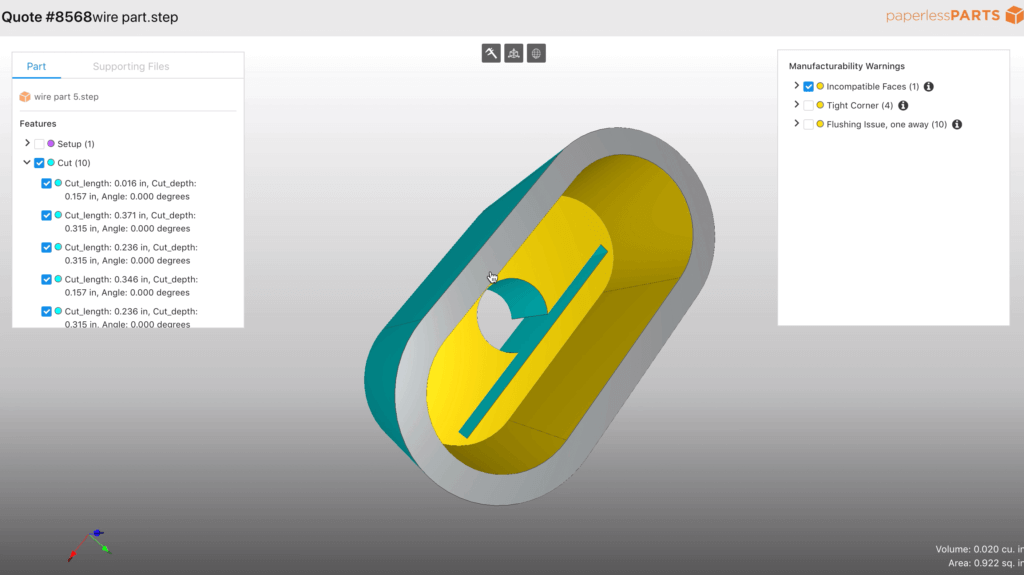

Lathe, Sheet Metal, and Wire EDM in Beta

Paperless Parts now has beta support for the following manufacturing processes:

1) Lathe

2) Sheet Metal

Including how parts are unfolded

3) Wire EDM

Note: These manufacturing processes only work on the new Operations interface. If you are interested in enabling them for your shop, contact us at [email protected].

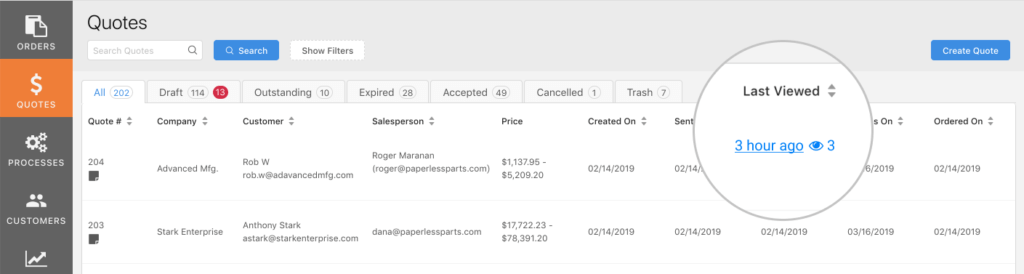

Track How Your Customers View Digital Quote

The Quotes list now shows you the number of views on your Digital Quote.

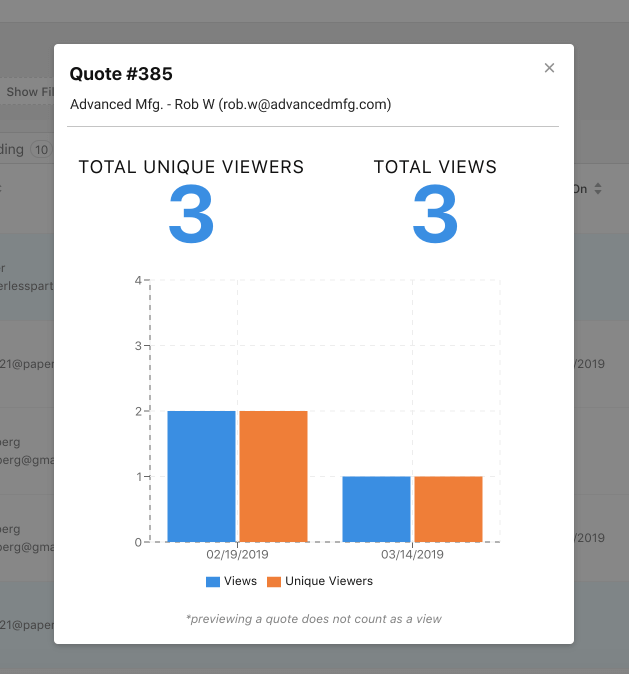

When you click on the link, you can see the number of views and unique viewers of the quote you sent. If you see that your customer has viewed the quote multiple times, give them a call to find out why they have not placed their order.

Online Metals Pricing Recommendation Improvements

The Online Metals Pricing Recommendations now references over 27,000+ stock material to better guide you through your quoting process.

Everything we build is based on feedback from our customers. Ready to get started with operations or want to share your feedback on these changes? We’d love to hear from you. Contact us at [email protected].

If your job shop is not using Paperless Parts yet, sign up for a demo today.

– Roger Maranan

Roger Maranan is the Head of Product at Paperless Parts. He has spent his career focused on building products for manufacturers and engineers. He holds a B.S. Mechanical Engineering from Boston University.