Quote Faster and Increase Your Revenue with Paperless Parts

The world is rapidly changing for custom parts manufacturers. A small number of well-funded players are beginning to dominate the market for custom manufactured parts. The expectations of parts buyers are changing too. A recent survey shows that 53% of buyers expect a response to their RFQs in 24 hours or less. Where should manufacturers look for growth opportunities in an increasingly competitive market? Learn how you can quote faster and increase your revenue to ensure that your shop doesn’t get left behind.

Overengineered Quotes–The Revenue Opportunity You Already Have

In speaking to hundreds of custom parts manufacturers, the average win rate is about 30% for quotes sent. For most custom parts manufacturers, teams spend countless hours working on quotes. This includes calculating material requirements on pen and paper and spreadsheets, programming to determine run times, scanning CAD and prints for manufacturability issues, admin time entering data into your ERP system, and much more. Manufacturers waste so much time and energy, especially when they lose 70% of quotes. Instead of making parts, the most experienced machinists are overengineering quotes. Overengineering increases quote turnaround times. Longer response times decrease a shop’s chance of winning the work.

“Today’s customers have little patience for waiting a few days to a couple weeks to receive a quote for a job,” says Dan Villemaire, President of C&M Precision Tech in New Hampshire. “In this increasingly fast-paced, competitive environment, we simply have to reduce the time and effort required to create and deliver quotes, without negatively impacting the accuracy of our job estimates.”

Fortunately for Dan Villemaire and other manufacturing business owners, they use Paperless Parts to help streamline their quoting process and grow their business.

Streamlined Communication, Faster Quoting, and Revenue Growth

Paperless Parts is the secure, ITAR-compliant manufacturing platform built to streamline the communication and quoting for custom parts manufacturers. It supports a variety of manufacturing processes including CNC milling and turning, sheet metal, additive, lasercut, waterjet, and wire EDM.

As Villemaire states, “With Paperless Parts, we can create more accurate quotes more quickly—increasing the overall volume of quotes and shortening our quote-to-cash cycle—while reducing quoting overhead and boosting the overall efficiency of our shop. Paperless Parts gives us the quoting agility and flexibility that we need to continue to grow our business.”

The platform does this in 3 ways:

- Streamlining the communication in the shop and with customers.

- Leveraging geometry to drive fast and accurate quoting.

- Providing customers a digital experience that helps manufacturers capture expedite value.

Streamlining Communication

Paperless Parts gives everyone in the shop, from the estimators in the front office to the operators on the floor, the ability to view 2D and 3D CAD replacing the need for additional CAD licenses or downloading stand alone viewers. All files are uploaded to one place, capturing the full technical data package of parts, ensuring that everyone has what they need to do their job.

Teams can communicate on details right in the CAD file, highlighting features that might require special tooling or details that need customer input.

“The built-in Paperless Parts 3D CAD viewer makes communication with the customer during the quoting process quick and easy,” says Paperless Parts customer Justin Quinn, President of Focused on Machining based in Colorado. “With Paperless Parts, we can identify, highlight, and comment on a feature of the part in question and send a link to the customer through which they can view the identical feature, highlight, and my comments about it. This helps us more easily deal with potential manufacturing issues during the quoting process, such as showing the customer how a feature like a sharp corner that increases machining costs can be modified to reduce the price.”

Paperless Parts users communicate in the context of the CAD model to chat with their team, customers, and other people.

Leveraging Geometry to Drive Fast and Accurate Quoting

To streamline quoting, Paperless Parts analyzes the geometric features from 3D part files to estimate operations and quickly generating pricing. To increase accuracy and consistency in the quoting process, the platform enables manufacturers to create templates around they quote, automatically adding operations used for their different manufacturing processes. All pricing formulas can be customized to how each manufacturer prices their operations.

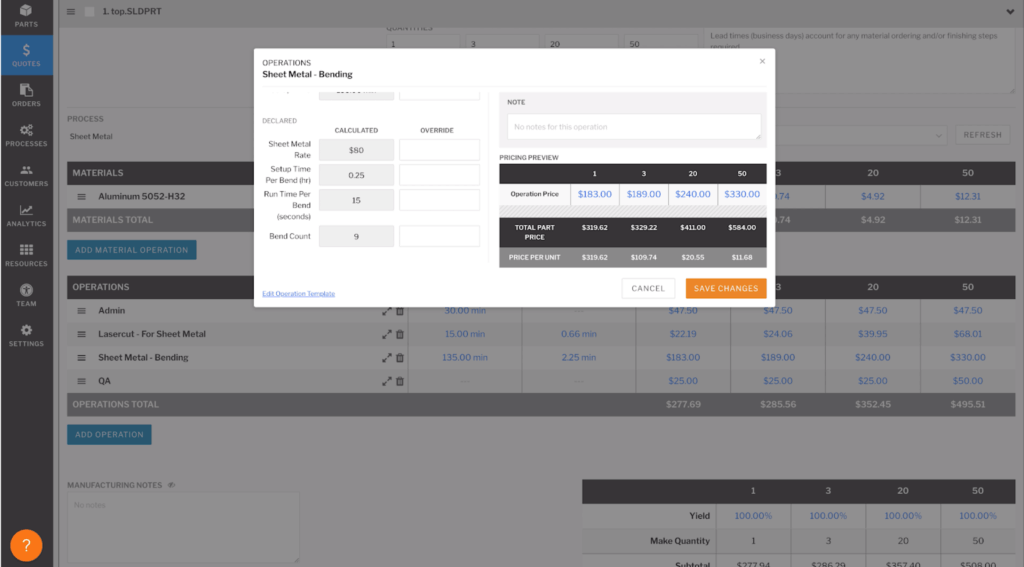

Paperless Parts makes it easy to generate quotes based on the part geometry. In this image, the number of bends are automatically identified to generate pricing for a part.

With the part geometry, the platform also estimates material pricing and even provides instant pricing recommendations from metals vendors like Online Metals. Additionally, the geometric analysis will identify design for manufacturability (DFM) issues, enabling teams to catch issues before they become problems.

“Time is valuable, and with Paperless Parts, we can create and send out 20 quotes in the time that it used to take us to complete one,” notes Andrew Reeves, Business Development and Department Manager at Vaupell Rapid Solutions.

A Better Customer Experience and Expedite Revenue

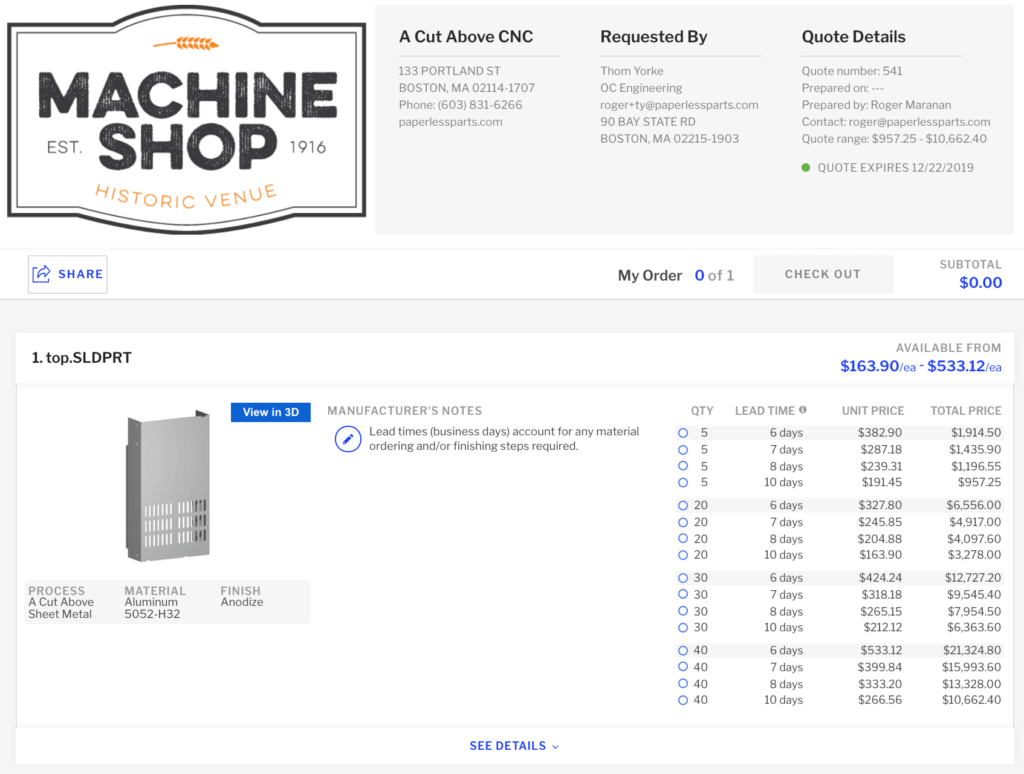

In addition to responding to quotes faster, manufacturers using Paperless Parts are able to provide their buyers a better buying experience with the Digital Quote. A big value of the Digital Quote is the ability for the manufacturer to provide expedite options, removing the awkward negotiation that happens when a customer wants their parts sooner.

Villemaire notes, “We were surprised by the fact that many customers choose to pay for expedited delivery. In just the first three months of using Paperless Parts, we received $40,000 in additional expedited revenue that we would not have seen in the past.”

An example of the Digital Quote with expedites.

A Competitive Advantage with Paperless Parts

With how the world is changing for manufacturers, it is easy to look to new machines, shop floor automation and robotics, and sensors for machine monitoring as ways to grow. These all seem like logical approaches, however the true key to unlocking growth in your business is the ability to drive increased profitability by leveraging the people and processes you already have. With Paperless Parts, manufacturers are able to focus on providing a better service to their customers and get higher profitability from the work they are doing, which makes investing in new technologies even easier.

“We implemented Paperless Parts in 2017, and our annual revenue increased more than 70 percent from 2017 to 2018, with expectations for revenue growth again in 2019,” Reeves explains. “While Paperless Parts isn’t the only reason that we’ve grown, it’s a substantial part of our success. We’re now using Paperless Parts analytics to justify investments in new capital equipment, including a new fused deposition modeling (FDM) machine and a new 5-axis CNC machine.”

To learn more, request a demo today.